Delta Motion Controllers

Delta Motion Controllers

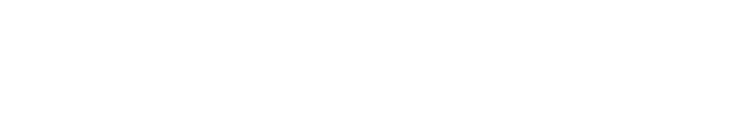

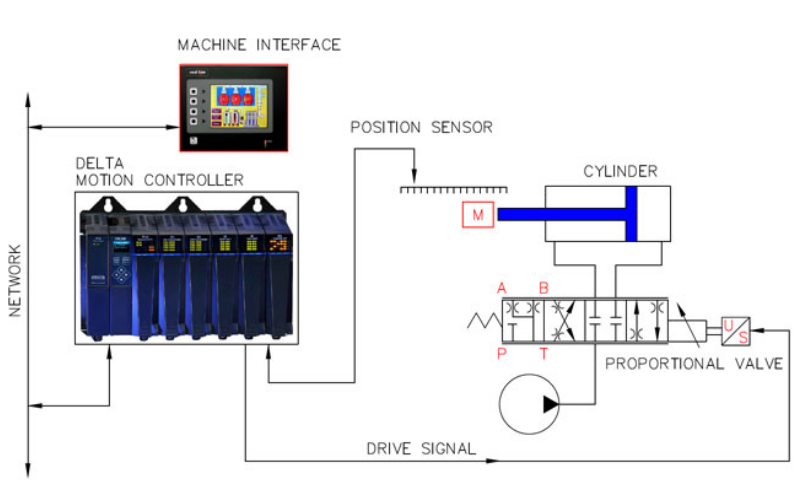

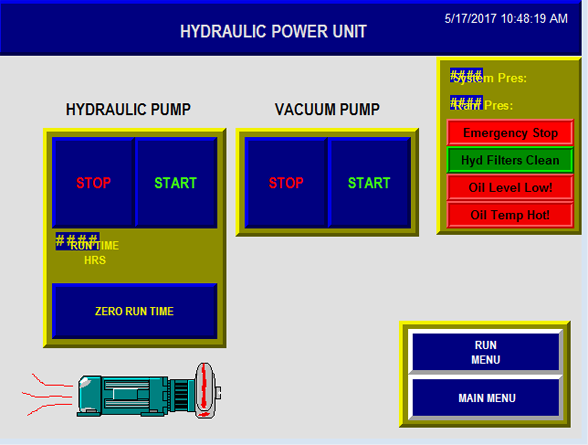

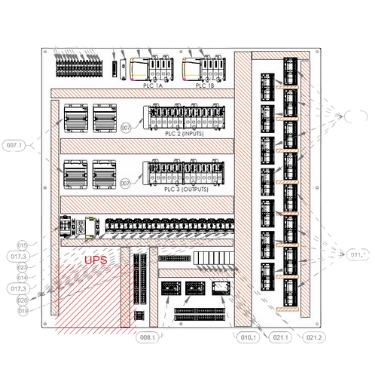

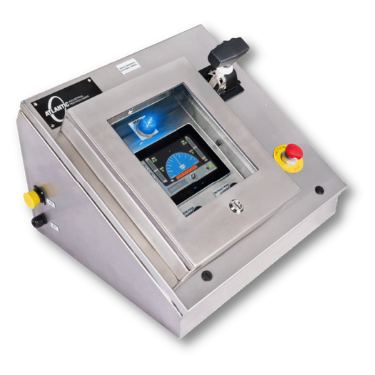

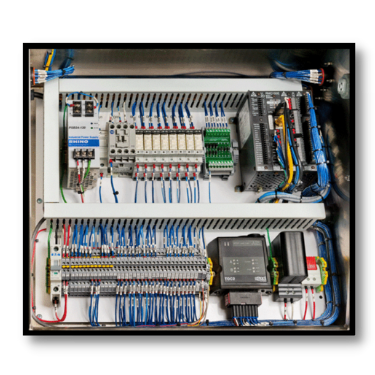

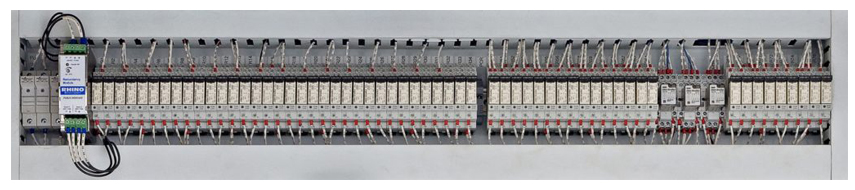

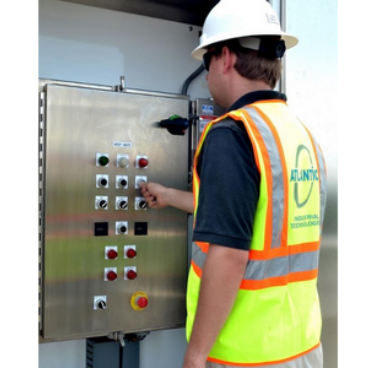

For high performance Motion Control, Delta Computer Systems offers leading technology for single to 16 axes of control. Atlantic is a certified System Integrator and distributor for the Delta product. We have decades of experience in closed loop servo controller programming. Call us to discuss your system.

RMC75 1-2 axis – | Single and dual axis motion controller