Atlantic’s Turbine Jacking Oil Pumps

…specially designed to reduce high friction in turning gears between rotor and bearings during start up, shut down and periods of slow speed

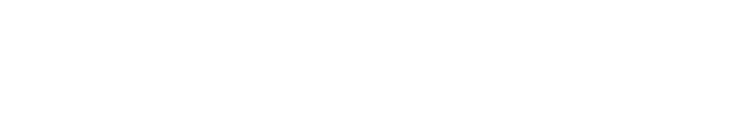

Atlantic’s Isolated Output Jacking Oil Systems for rotating equipment are designed to provide a forced hydrostatic oil film to multiple injection points–up to 8 per pump–by isolating pistons from our hydraulic pumps to dedicated lines.

Part Number AF-11456

Part Number AF-11456

The Atlantic Difference:

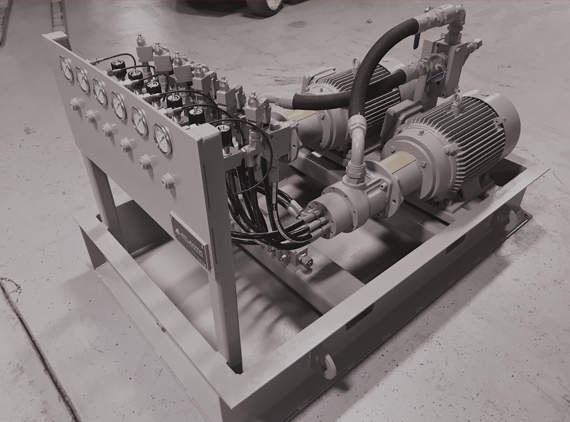

Isolating Checkball Piston Pumps

- Allows for independent fixed pressure and flow into each injection point along the rotor shaft

- Now all injection points receive the required flow and pressure even if other injection points have insufficient backpressure

If one of more injection points have more clearance than others those points consume more hydraulic fluid, reducing flow and pressure from other injection points. But with Atlantic’s Isolating Checkball Piston Pumps Mfg by Dynex,those issues are eliminated and instead fixed flow is delivered to designated injection points based on manually or electronically adjustable flow and pressure. Each piston in the pump is now an independent pumping unit while guarantee fixed flow to each injection point

Atlantic’s Isolated Output Jacking Oil Systems Features:

- Pump flow options from 2 GPM to 18 GPM

- Up to 8 forced pressure outlets per pump

- Pressures up to 4000 PSI

- Redundant pump set option

- Independent pressure & flow settings

- Filtration options down to 2 microns

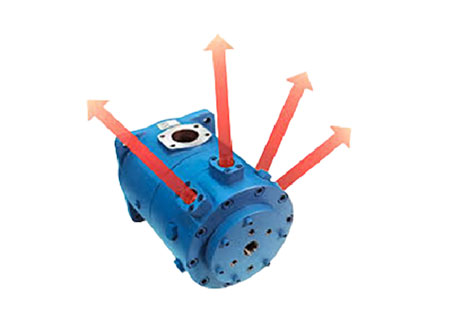

How Do Turbine Jacking Oil Pumps Work?

Essentially, they lift heavy turbine rotor shafts until self-lubrication (hydrodynamic lubrication) is attained or the turbine itself is in turning gear. Specifically, the heavy rotor is prevented from rubbing against the bearing’s white metal or babbit bedding area at low speeds through the production of a hydrostatic oil film when the rotational speed is too low to produce a hydrodynamic oil film. This hydrostatic film reduces the break-away torque during run-up of the turbine rotor during high frictionstart up, shut down and slow speed (turning gear) periods.