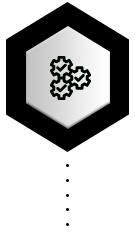

Since Hurricane Katrina, Atlantic has designed, manufactured and commissioned dozens of hydraulic & control systems on Flood Control Gates throughout the USA.

Our team of field engineers will follow the hydraulic system to site, start it up, adjust sensors, tweak software if necessary and work with the GCs & Owners until all specifications and requirements are met.

Atlantic’s systems control gates to protect New Orleans at 7 different sites in the New Orleans region.

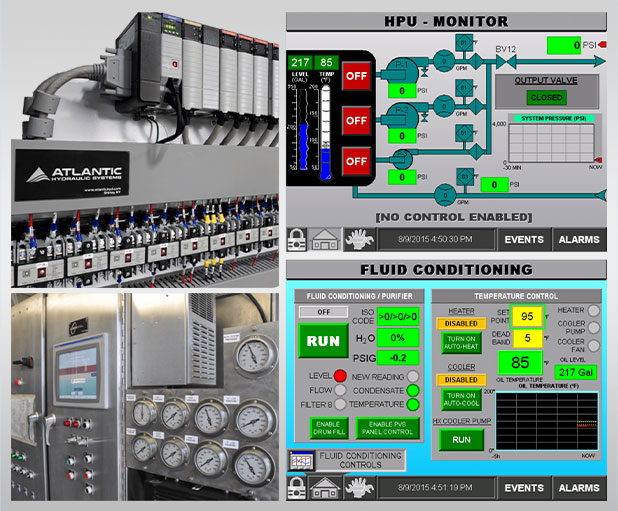

For 40 years Atlantic Hydraulic Systems has served to advance various industries in protecting our cities and country.

Engineering

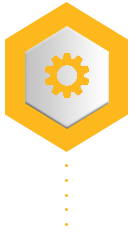

Our staff of hydraulic, mechanical and controls engineers will take you through the process of discovery which is the study of the specifications and owner needs all the way final acceptance tesTIng of your flood control system. From the submittal process and often the re-submittal process all the way through final onsite adjustments, our team experience with dozens of floodgate commissioning will shine.

Our Process

DISCOVERY

During discovery we listen to your needs and collaborate with your team to fully understand, and conquer, the challenges you face.

MANUFACTURING

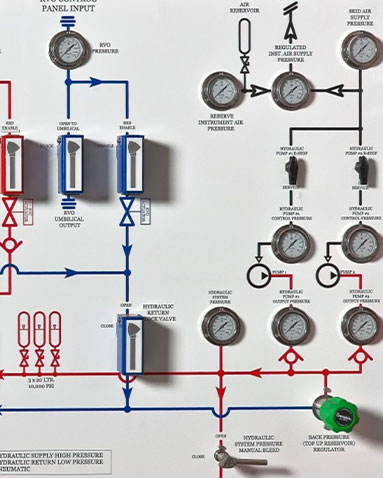

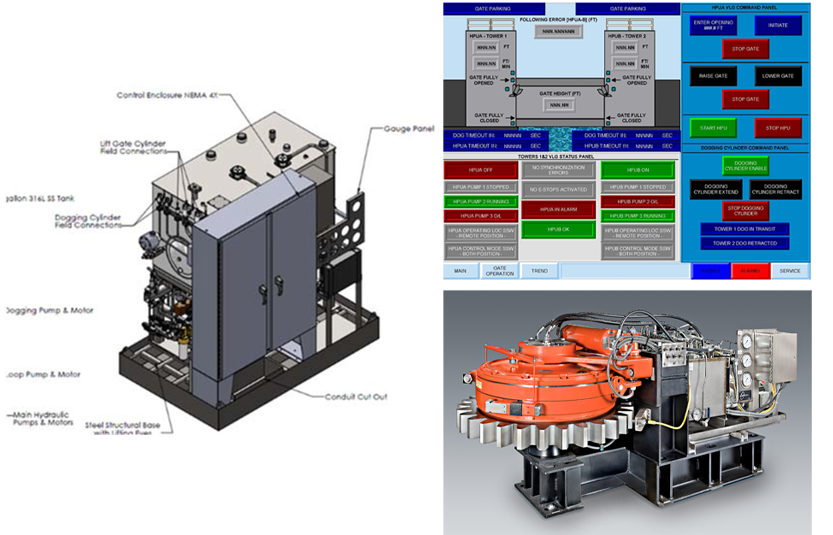

All systems are manufactured at our 18,000 sq-ft power unit & controls facility where the design engineers can oversee the manufacturing process.

COMMISSION

When required, we follow our equipment to sight and work closely with trades to successfully integrate and commission our machinery and controls.

DESIGN

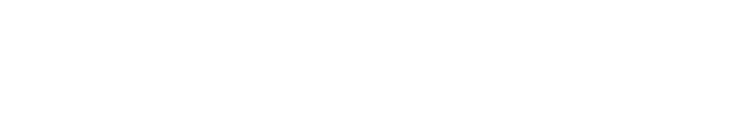

The design phase is where we submit drawings, schematics and BOMs so all aspects of the system are communicated and understood prior to manufacture. This important communication is to eliminate any surprises in the delivered product.

TEST

All hydraulic systems are run at full pressure and or flow and control systems are fully testing by our engineers. In person factory witness testing is available and video factory testing (VFAT) is becoming more common.

DISCOVERY

During discovery our engineers dig into your application. The information is used to design the most efficient system possible that meets your needs.

DESIGN

The design phase is where we submit drawings, schematics and BOMs so all aspects of the system are communicated and understood prior to manufacture. This important communication is to eliminate any surprises in the delivered product.

MANUFACTURING

All systems are manufactured at our 18,000 sq-ft power unit & controls facility where the design engineers can oversee the manufacturing process.

TEST

All hydraulic systems are run at full pressure and or flow and control systems are fully testing by our engineers. In person factory witness testing is available and video factory testing (VFAT) is becoming more common.

COMMISSION

When required, we follow our equipment to sight and work closely with trades to successfully integrate and commission our machinery and controls.