For more than 35 years, our clients have placed their trust in Atlantic

to deliver superior hydraulic, mechanical and control systems that help keep our service men and women safe, while protecting our country and communities.

Three of the top 10 defense contracting companies in the world, as well as the U.S. Navy NASA, and many other great organizations rely on Atlantic to help them meet their custom product goals, timelines and budget requirements. All of these factors are critical to the success of the design and manufacture of their systems..

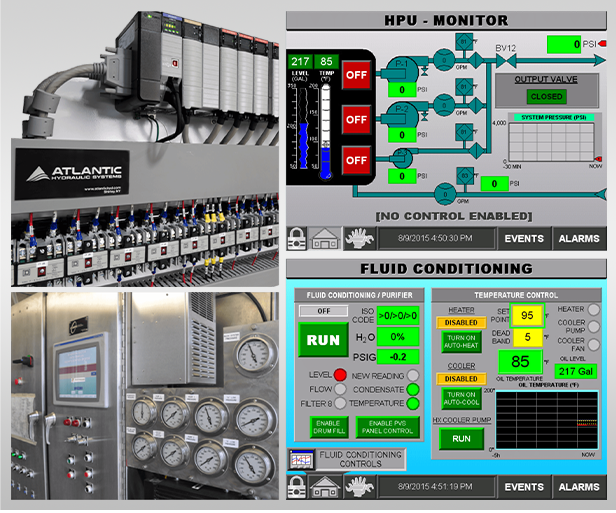

Hydraulic Test Stands,

Control & Monitoring Systems

Engineered Portable and Stationary Control & Testing Systems

Hydraulic Systems with Online Pressure, Flow,

Temperature & Particulate Monitoring

Custom Control Systems & software Development for Testing Systems

Deep Submergence, Surface Control Systems

& Motor controllers

Mechanically & electrically designed to meet military specifications from prototype to first article testing to production.

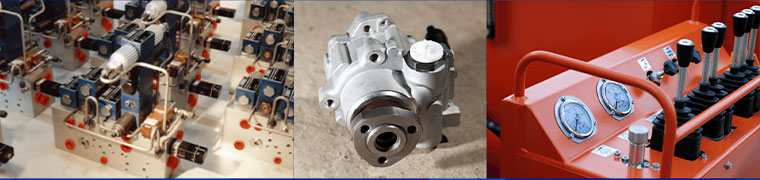

Custom Hydraulic Manifolds and Power Units for Submerged & Surface applications

Design of multifunctional hydraulic valve manifolds to efficiently operate cylinders, hydraulic drive motors, locking systems and more.

Systems compatible with

MIL-PRF-5606-H

MIL-PRF-6083

MIL-DTL-17111

and other hydraulic fluids

Atlantic provides engineering design services for both hydraulic and mechanical systems which include Finite Element Analysis, Reliability Calculations and First Article Test Procedures.

Hydraulic Testing & Ground Support Equipment

Systems Custom Design & Manufacture

Atlantic has the solutions and expertise for the design of hydraulic &control systems for government and military operations.

Our engineering and quality teams

Understand the critical nature of military applications as well as the extensive testing required to assure reliability of these products.

Our Process

DISCOVERY

During discovery we listen to your needs and collaborate with your team to fully understand, and conquer, the challenges you face.

MANUFACTURING

All systems are manufactured at our 18,000 sq-ft power unit & controls facility where the design engineers can oversee the manufacturing process.

COMMISSION

When required, we follow our equipment to sight and work closely with trades to successfully integrate and commission our machinery and controls.

DESIGN

The design phase is where we submit drawings, schematics and BOMs so all aspects of the system are communicated and understood prior to manufacture. This important communication is to eliminate any surprises in the delivered product.

TEST

All hydraulic systems are run at full pressure and or flow and control systems are fully testing by our engineers. In person factory witness testing is available and video factory testing (VFAT) is becoming more common.

DISCOVERY

During discovery our engineers dig into your application. The information is used to design the most efficient system possible that meets your needs.

DESIGN

The design phase is where we submit drawings, schematics and BOMs so all aspects of the system are communicated and understood prior to manufacture. This important communication is to eliminate any surprises in the delivered product.

MANUFACTURING

All systems are manufactured at our 18,000 sq-ft power unit & controls facility where the design engineers can oversee the manufacturing process.

TEST

All hydraulic systems are run at full pressure and or flow and control systems are fully testing by our engineers. In person factory witness testing is available and video factory testing (VFAT) is becoming more common.

COMMISSION

When required, we follow our equipment to sight and work closely with trades to successfully integrate and commission our machinery and controls.