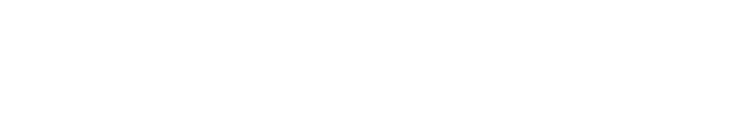

Atlantic’s Turbine Lube Oil Skids

and pressure to all bearings, control equipment and seals

Lube oil skids are designed under strict standards to keep lube oil physical conditions like humidity, viscosity, temperature & cleanliness under specific values that permit the best performance for gas turbine, gas compressor turbines, steam turbine, reciprocal engines, etc.

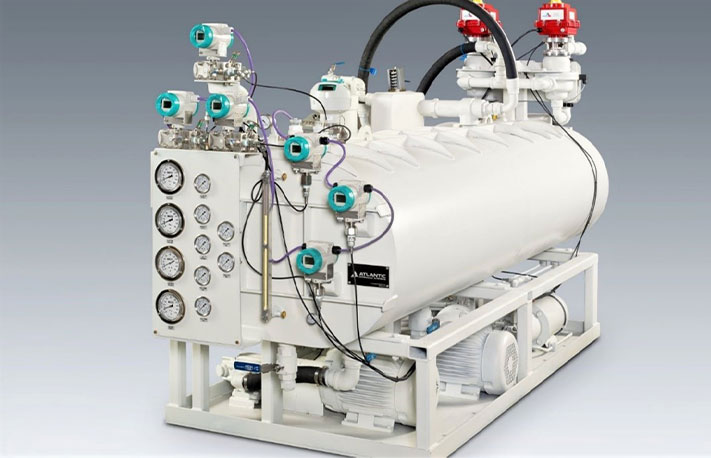

Control & Instrumentation:

Atlantic tailors it’s engineering to fit special customer requirements for process monitoring and lube oil under PLC and SCADA remote monitoring

Alarming You Of Change

In Oil Condition:

Regular instrumentation such as temperature, pressure and oil level transmitters will constantly be feeding data to the control system or SCADA.

To fully track the oil condition our systems can contain both free water and high particulate alarm systems. Automated oil samples will be pulled on an

intermittent basis and results transmitted back to the control system.

Water causes great harm to oil and bearings, knowledge of excess is of great

importance.

Atlantic's Turbine Lube Oil

Systems Feature:

- Single or Duplex (redundant) fixed

displacement pump flow - Accumulator (stored oil) backup

- Single or Duplex 2 micron filtration

- ASME Heat Exchangers

- Pressure, Flow, Temperature transmitters

- Filtration options down to 2 microns

- Vacuum Dehydration water removal