Seabrook Lift & Sector Gates

United States Army Corps of Engineers

New Orleans, LA

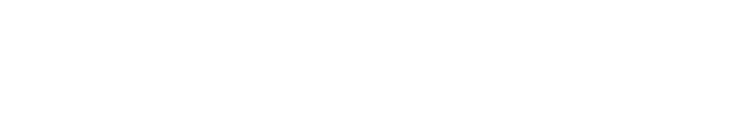

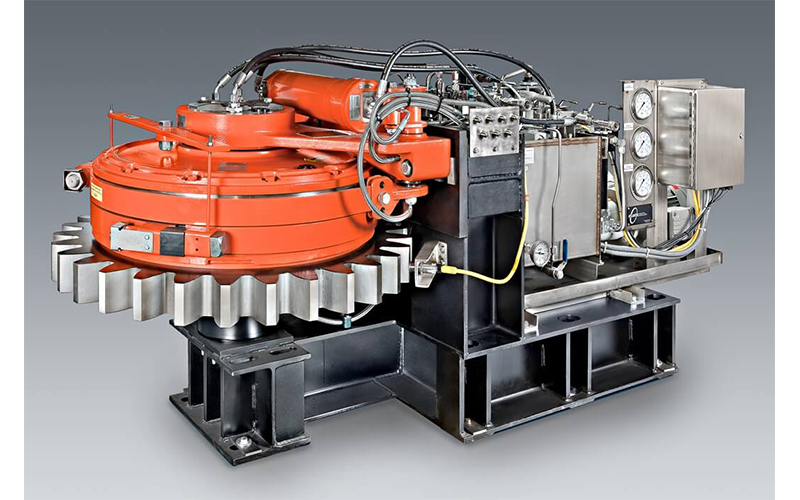

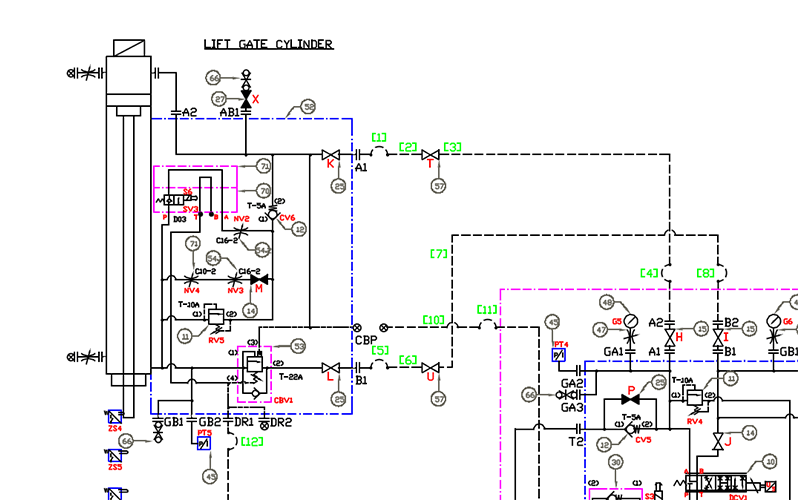

In the 12 years since Hurricane Katrina, the U.S. Army Corps of Engineers has nearly completed one of the world’s most remarkable hurricane protection systems to encircle New Orleans. The Seabrook Floodgate Structure is a flood barrier which is designed to protect the surrounding areas from a storm surge from Lake Ponchartrain. It consists of two 50 ft wide vertical lift gates and a 95 ft wide sector gate.

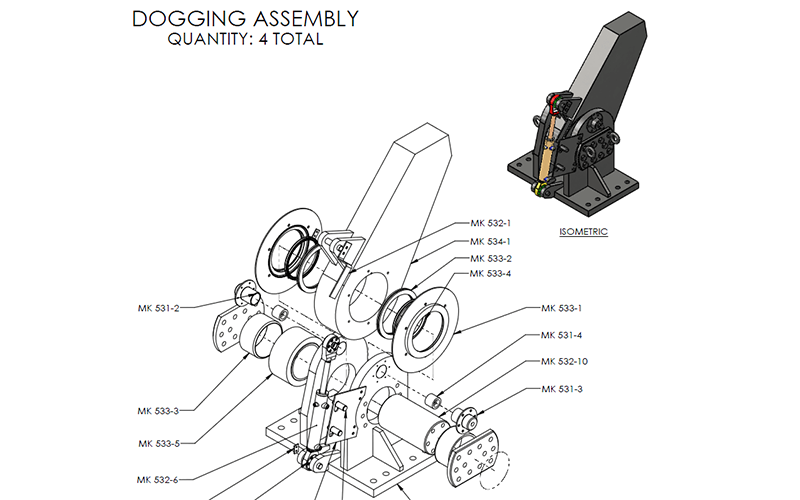

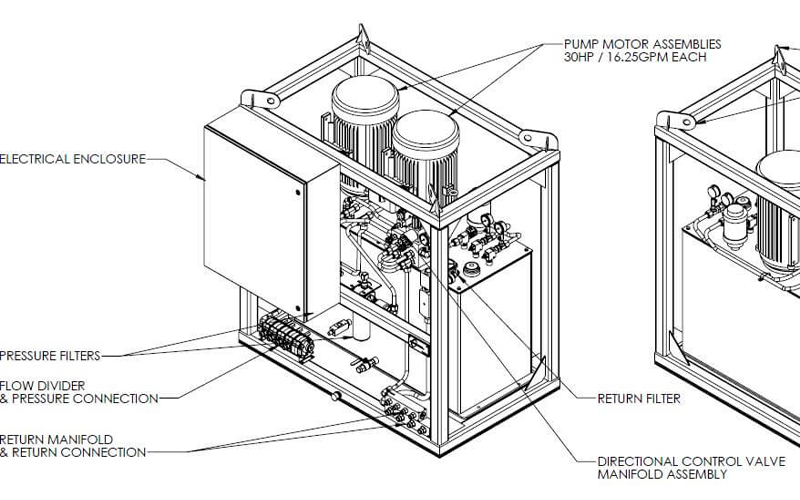

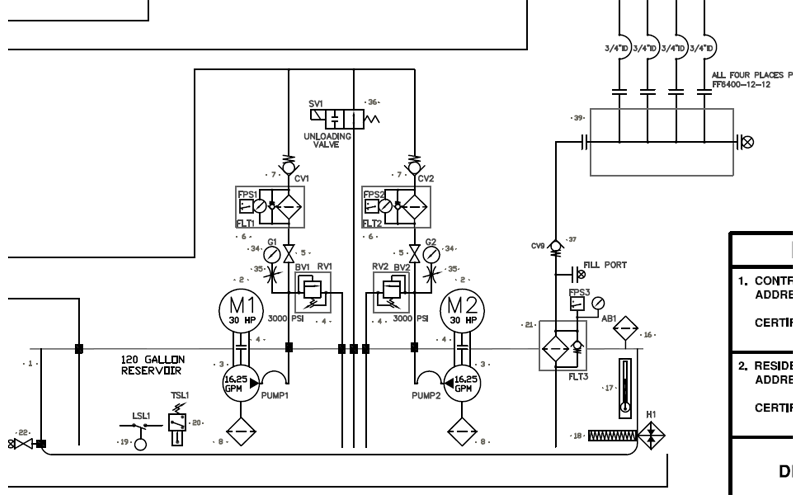

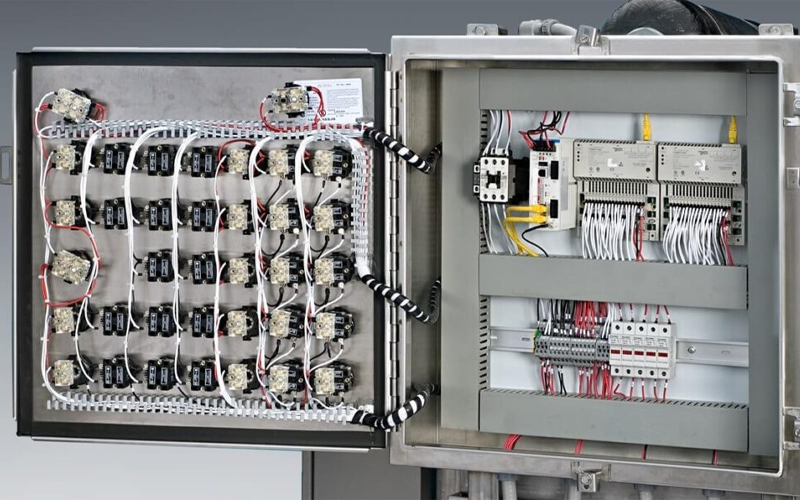

Atlantic Hydraulic Systems designed, manufactured and commissioned the flood gate hydraulics and control systems at Seabrook Gates. Atlantic on-site technicians directed the installation of the HPU, hydraulic cylinders, hydraulic plumbing and both high voltage and control wiring.

The gates are controlled using a user-friendly graphic interface and provides closed loop position control of the gates and safety interlocks with the gates locking mechanisms.

Read our White Paper presented at Heavy Movers Conference 2015

Specifications

Metropolitan Ave Bridge Hydraulics

NYC Dept of Transportation

New York, NY

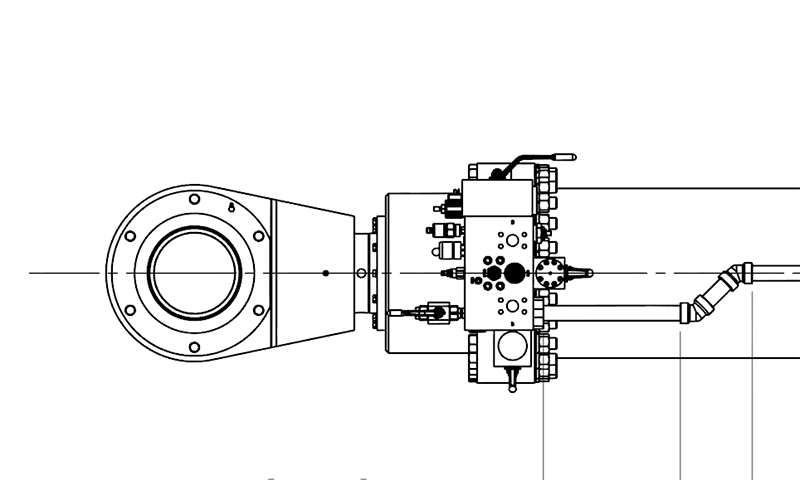

Atlantic Hydraulic Systems provided the design and manufacture of both the temporary and permanent hydraulic systems during the bridge’s machinery replacement due to Hurricane Sandy.

Two 60 HP hydraulic power units and four 10″ bore x 96″ stroke cylinders drive the two massive leaves of the bridge.

Four 7.5 HP hydraulic power units drive the tail locks into place.

Other Movable Bridge Hydraulics projects include:

- Willis Ave Bridge

- 145 St Bridge

- Metropolitan Ave Bridge

- Hamilton Ave Bridge

- 3rd Ave Bridge

- Marine Parkway Bridge

- Beaver Dam Bridge

Specifications

New Orleans Lift Gates

Army Corps of Engineers

New Orleans, LA

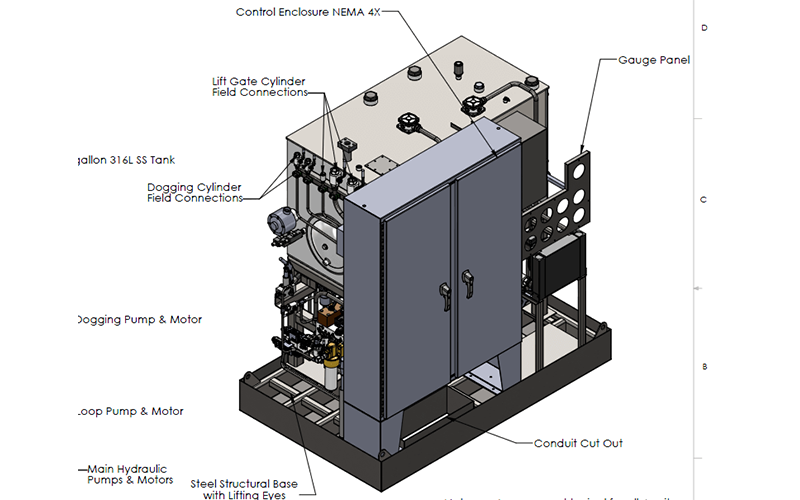

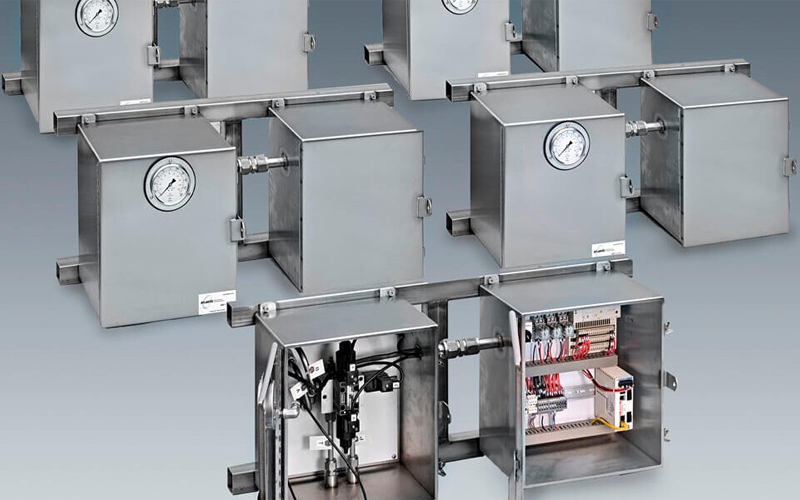

After Hurricane Katrina Atlantic Hydraulic Systems was commissioned to design, manufacture and install the hydraulic system for the Orleans Avenue Gates.

Five hydraulically driven winches were placed to lift and lower massive gates to prevent water flow in the canal during a storm.

The HPU is designed to communicate with the municipal SCADA systems as well as to be run manually.

Other New Orleans locations where Atlantic Hydraulic Systems were utilized are:

- Seabrook Gates

- Bayou Segnette Complex

- Charles Parish Navigable Closure

- Floodwall at St. Bernard & Plaquemines Parish

- Inner Harbor Navigation Canal, St Bernard Parish

Specifications

North Dakota Flood Control

US Army Corps of Engineers

Williston, ND

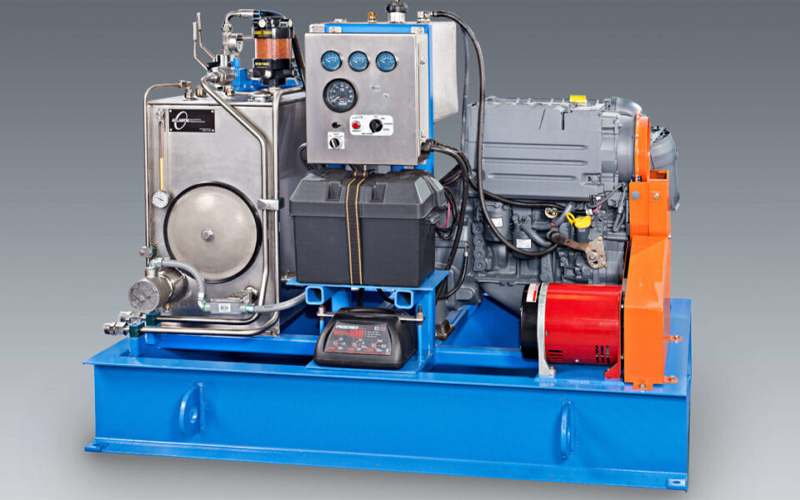

A by product of the Oil Fracking Boom in North Dakota is the drilling wastewater produced in the process.

Oil companies produce millions of gallons of salty, chemical-infused wastewater, known as brine, as part of drilling and fracking each well.

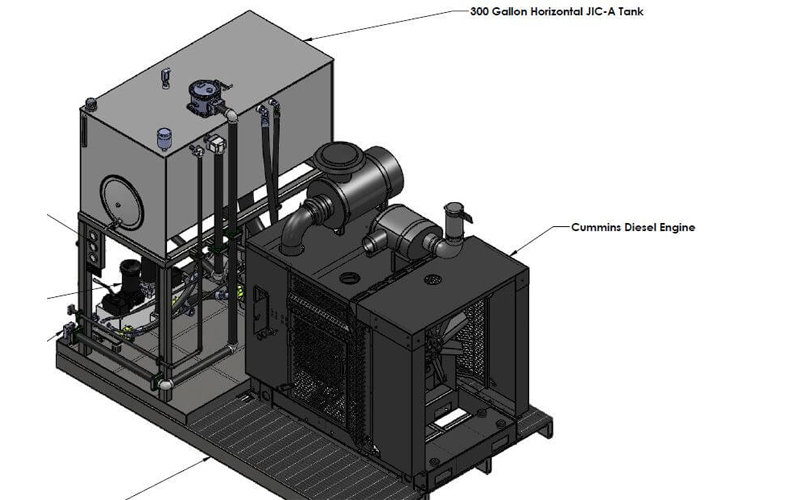

Atlantic Hydraulic Systems was chosen to design and manufacture diesel driven hydraulic system to drive the large water pumps that dispose of the toxic water.

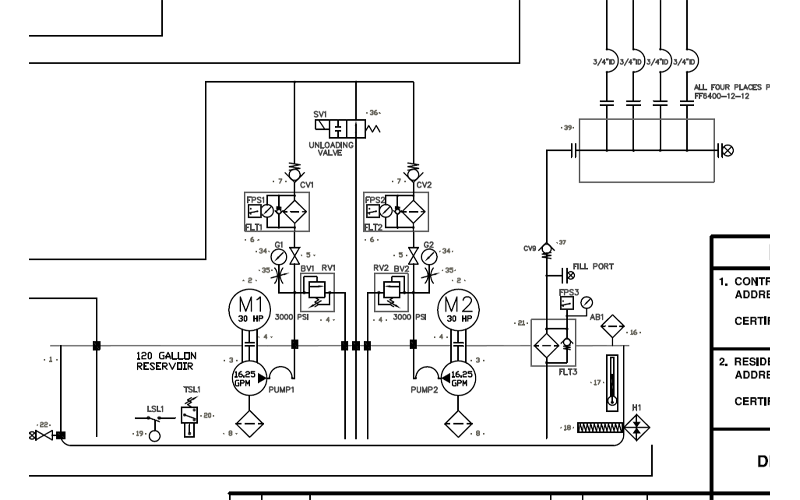

The 360 HP Cummins Diesel Engine drives two Parker PV series piston pumps to output 200 GPM of hydraulic oil at 4000 PSI.

Three Parker F11 hydraulic motors per HPU were utilized to drive the 18,000 GPM water pumps on this project.

Specifications

Stay Up To Date With Latest Blogs

Air in your Hydraulic Oil?

How do I prevent air from getting in to my hydraulic oil? Does it sound like there are marbles in your hydraulic pump?

Raising the Roof in Lakeland Florida

Fun engineering has always been a staple at Atlantic Industrial Technologies. We were honored to be selected to design, manufacture, install, and commission..

5 Best way to Design a Hydraulic

System that runs cool

Very simply… the best way to have a cool running hydraulic system is to design it to draw the least amount energy as..