In these days of increasing energy costs as well as the push to lower our carbon footprint, there are some simple ways to design a hydraulic system that consumes less energy.

This blog will cover several key areas to consider in the design of an efficient hydraulic power unit. You will learn how all of these parts come together to make a complex and energy-efficient system.

Correct Hydraulic Pump Specification

When the hydraulic pump is specified for an application, it should be sized close to the system flow requirements unless flow upside possibilities are required for the system.

Pump Style Selection

The two basic hydraulic pump types are fixed and variable displacement.

The fixed displacement pump will always produce flow based on the motor speed and the pump’s displacement. If the system is idle but still running, the fixed displacement pump will produce flow and push oil over the relief valve using energy.

It is common to “dump” this oil back to the tank freely using an unloading valve or a directional valve with an open center. Another option is to lower the pressure during idle times with a 2-pressure relief valve or proportional relief valve. Fixed displacement pumps are often preferred for low usage applications where the unit is not running all day.

The variable displacement pump will only produce flow when the outlet pressure is less than the set pressure for the pump. Once the pump pressure is reached the pump goes into “neutral” automatically and waits for the pressure to drop to produce flow again.

The pressure often drops when a valve is opened to move a cylinder or hydraulic motor. These types of pumps still use energy even when spinning in neutral. Lowering this deadhead pressure during idle times will decrease energy usage. Variable displacement pumps generally use less energy than fixed displacements pumps.

Use of Inverter Drives

A good device to consider if you want to make your power unit more efficient, as it allows you to adjust the output speed of the unit’s motor and pump; some modern drives can make units 50% more energy efficient while also reducing noise levels and environmental impact.

System piping

In the design stage of a power unit and its installation, it is always best to try to minimize and bends in the system as this will allow the hydraulic fluid to flow more freely and efficiently. Pipe sizing is crucial to minimize pressure losses that add to the power requirements.

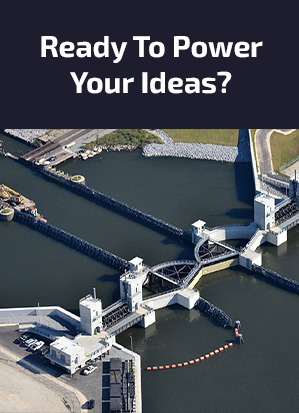

The Uses Of Hydraulic Power Systems

When deciding what kind of Hydraulic Power system that you will purchase it is best to look at your individual needs. What pressure and flow will you need? There are options ranging from up to 25HP to over 100HP to suit all situations.

Hydraulic power systems are used in everything from bridge building to general construction. At its simplest, you may have hydraulic power used firsthand in the form of a hand jack then from a 1500 HP diesel engine. From this example, it is easy to see how a low amount of force can be spread out to accomplish much more work.

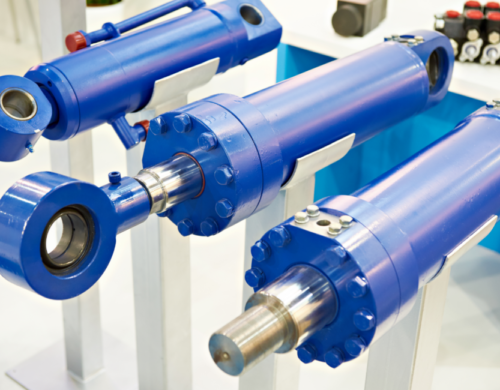

A full hydraulic system often includes an accumulator, hydraulic cylinder, control valves, heat-exchanger, relief valve, pump, filter, and reservoir.

Safety

It is important to remember that Hydraulic systems are heavy pieces of machinery and therefore require specific training to properly use them. There are training courses available to certify any of your personnel who might be using this system.

The biggest mistake people make is thinking that because it is just fluid that it is not dangerous. When in fact the fluid itself can be incredibly dangerous causing serious burning.

Furthermore, even though these systems are small they can produce a lot of force. Make sure that if you are looking into hydraulic systems that you fully understand the safety measures required to maintain them.