If you want to replace or retrofit a Hydraulic Power Unit, you must understand the key components that have made modern HPUs smaller, quieter, and more efficient.

Gone are the days of being limited to a fixed-speed Hydraulic Power Unit. In fact, the new variable-speed HPUs are far more energy efficient, and they are starting to dominate the market. Add in the fact that these new units include built-in sensors, diagnostics, and even cloud capabilities, making them very easy to connect to an IoT (Internet of Things) environment, and it’s fairly easy to see why they have become so popular. The sheer amount of predictive maintenance data alone makes the investment worth it!

The most important part of replacing a Hydraulic Power Unit is understanding how the modern hydraulic system design differs from the older conventional systems in aspects like size, noise, energy efficiency, connectivity, and total cost of ownership. Let’s take a look at those differences…

The Main Differences Between Conventional and Modern Hydraulic Power Units

Hydraulic Power Unit Size

HPU size is often determined by the size of its hydraulic fluid reservoir. For traditional HPUs, the reservoir minimum is normally two to five times the maximum pump flow.

Conversely, modern HPUs can be designed to a 1:1 flow/reservoir size ratio due to pump controls, advanced manifold design, and the use of variable frequency-driven motors to drive the pumps. As a result, a unit that produces a max flow of 150 GPM per minute may only need a reservoir capacity of 150 gallons, or 75 percent less reservoir capacity than a traditional HPU.

Hydraulic Power Unit Noise

By operating at variable speeds, modern units are quieter because they don’t demand their full power at all times. Instead, they are only delivering the power needed at any given time.

Furthermore, modern systems can be built from materials that dampen sound and minimize vibrations using designs like a liquid-cooled motor, compact arrangement of components, unitary housing, and built-in sound-insulating mats.

Hydraulic Power Unit Energy Efficiency

A fixed-speed HPU operates at 100 percent motor speed at all times. In turn, any energy not being used to do work is converted to heat. This all results in higher energy costs and excess heat production that must be controlled using cooling – which requires even more energy.

Variable-speed systems adjust energy output to match the demands of the operation. As such, variable-speed HPUs have demonstrated energy savings of up to 80 percent. Lower, more controlled operating speeds also reduce the unit’s heat output, allowing it to run cooler and reduce or eliminate the need for additional cooling measures and their associated costs.

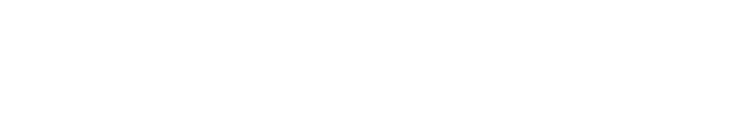

Hydraulic Power Unit Connectivity

With a modern HPU, access to cloud-based diagnostics and data analytics tools streamlines workflows and reduces the demand for personnel to capture critical data and troubleshoot equipment in person.

Some HPUs include case drain flow/temperature, particle counter, energy consumption, pump damage, and other monitoring parameters, with real-time access to performance and usage reports 24/7 via dashboards on a mobile device.

Hydraulic Power Unit Total Cost of Ownership

Modern variable-speed HPUs may be more of an investment upfront, but manufacturers with high energy costs driven by fixed-speed HPUs will see more value and a faster return on their investment.