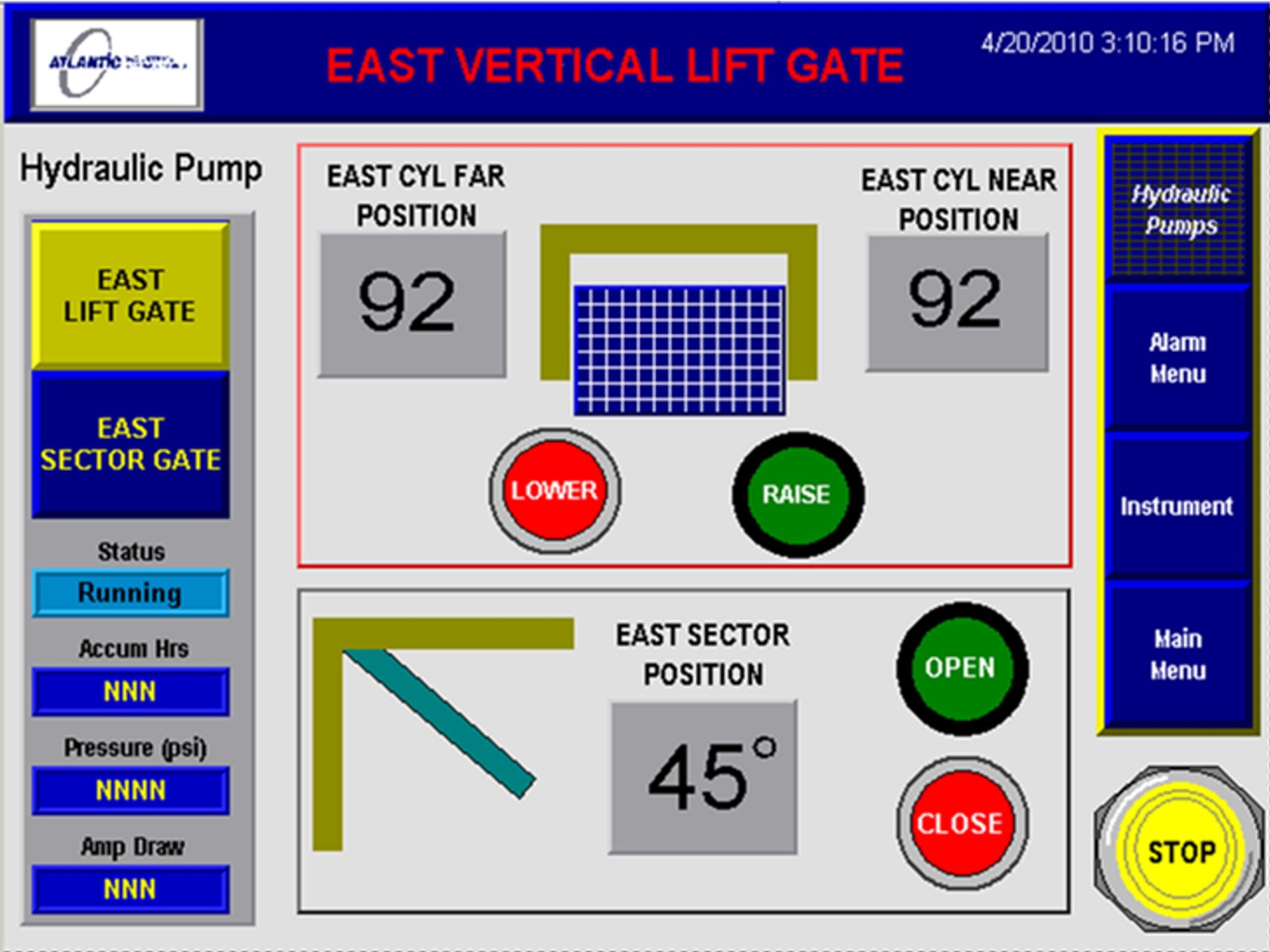

Electro-hydraulic systems combine the benefits of electrical signal processing with hydraulic drives to create versatile and reliable control systems. These systems can be categorized into three groups based on functionality, each offering unique advantages and applications.

1. Solenoids

The first group of electro-hydraulic systems uses solenoids to open or close hydraulic valves. The signal processing is performed using relay technology, making it suitable for applications with sufficient simple on/off control. These systems are typically used in agriculture, construction, and transportation industries.

2. Proportional Valves

The second group of electro-hydraulic systems uses proportional valves that allow for continuous adjustment to changing setpoints, resulting in better compensation for the progression of processes. The setpoints can be retrieved via machine controls or a programmable logic controller (PLC), and the signal processing is performed electronically. These systems are ideal for applications that require precise control and adjustments, such as in the chemical, food processing, and pharmaceutical industries.

3. Servo Valves

The third and final group of electro-hydraulic systems uses high-response proportional or servo valves. These systems use continuous sensors and electronic control amplifiers to execute the program via machine controls, such as numerical control (NC), computer numerical control (CNC), or direct numerical control (DNC). These systems suit applications requiring high precision and responsiveness, such as aerospace, defense, automotive, and manufacturing automation.

Electro-hydraulic systems have numerous advantages, including high power density, low maintenance, and long service life. They can operate under extreme conditions, such as high temperatures, pressure, and corrosive environments, making them ideal for challenging applications. Additionally, they offer precise control and can be easily integrated into existing systems.

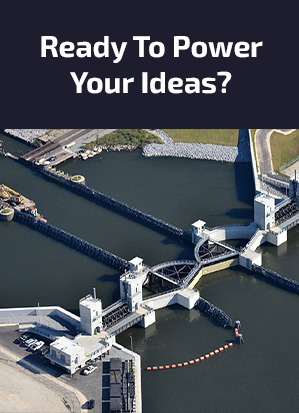

Examples in Different Industries

Aerospace

One example of an electrohydraulic system’s application is in the aerospace industry, where these systems are used in aircraft landing gears and flight control systems. Electrohydraulic systems’ high precision and responsiveness ensure the safe and reliable operation of critical components in these applications.

Construction

In the construction industry, electro-hydraulic systems are used in heavy machinery, such as excavators, bulldozers, and cranes. These systems provide precise control and enable operators to perform complex tasks efficiently and safely.

Manufacturing

The manufacturing industry uses electro-hydraulic systems in automated assembly lines, robotic arms, and packaging machinery. These systems offer high-speed and high-precision control, increasing productivity and reducing production costs.

Electro-hydraulic systems offer a reliable and versatile solution for various industries that require precise control and high performance. With their numerous advantages and applications, these systems continue to play a vital role in the advancement of modern technology.