Fluid Viscosity is sometimes referred to as dynamic viscosity or absolute viscosity. The fluid’s resistance to flow is caused by shearing stress within a flowing fluid and between a flowing fluid and its container. It’s basically the thickness of the fluid.

Many different factors have to be considered when specifying hydraulic oil viscosity, including system temperatures, pressures, and environmental factors.

Hydraulic components can suffer reduced lifespans and early failures if the wrong fluid is used. Pump and system performance and longevity can be significantly affected by using different viscous fluids.

The size and structure of molecule chains are crucial factors in measuring a fluid’s viscosity, and the larger the molecules’ thicker the fluid.

The viscosity of a fluid can be greatly affected by various elements, especially temperature. As the system temperature increases, the fluid viscosity begins to decrease. The opposite is true when system temperature drops.

Ideally, a hydraulic fluid that maintained constant viscosity would be the ultimate. Some hydraulic fluids perform better than others as temperature varies.

Multi-grade fluids typically have a high viscosity index meaning that they are less sensitive to temperature change than typical monograde oil.

How to Determine the Right Fluid Viscosity

The first thing that needs to be completed is to check on the acceptable viscosity grade of your hydraulic components, especially the hydraulic pump. Manufacturers will list what the optimal viscosity range is for their components (mainly pumps). Hydraulic fluid (oil) manufacturers will also give an oil viscosity range of their product based on temperature either on a chart or with two temperature data points for interpolation.

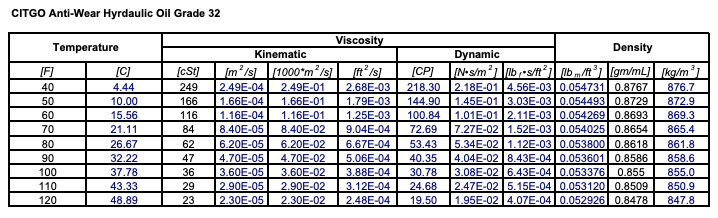

An example of a chart that shows the hydraulic oils’ viscosity range

An example of a chart that shows the hydraulic oils’ viscosity rangeThe proper design method is to choose an oil that sits well in the components, especially the pump. The hydraulic power unit must be designed to maintain the operating temperature range desired to keep in this range. This often requires heat exchangers or immersion heaters in the oil, depending on the application and ambient temperature. Instead of a fixed displacement pump, a pressure-compensated pump will often help hold the fluid temperature at a relative constant.

The optimal way to control temperature and, therefore, viscosity is during the initial design phase. Choose the right components and design a system that can keep oil temperatures at a relative constant.

Atlantic Hydraulic Systems has a skilled team of engineers who are always happy to guide you through hydraulic system requirements and specifications and advise you on fluid suitability.