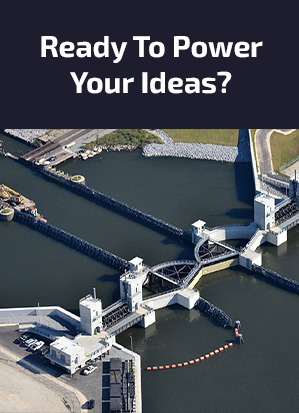

Flood events are becoming more frequent and more severe, placing pressure on public infrastructure and the agencies responsible for protecting communities.

For the Department of Environmental Protection (DEP), choosing the right hydraulic partner is not just a decision; it is a commitment to public safety. The DEP requires systems that are reliable, available, and engineered to perform under the most demanding conditions. Here at Atlantic Hydraulic Systems, we have become a trusted provider because we design every system with a single goal: consistent, uncompromising flood-control reliability.

The Critical Importance of Reliability and Availability in Flood Control

In any flood control system, reliability and availability are the two most essential performance characteristics. The system must operate exactly as intended, with minimal downtime, because failure at the wrong time could result in property damage, environmental harm, or safety risks.

Flood control infrastructure must operate when conditions are far from ideal. It must be engineered to perform even when power is lost, components fail, or environmental conditions worsen. This is the standard the DEP expects, and Atlantic Hydraulic Systems meets it through thoughtful, purpose-driven engineering.

Redundancy in System Design: Always Prepared for the Unexpected

A reliable flood control system must remain operational even when a main component fails.

Atlantic Hydraulic Systems incorporates multiple layers of redundancy to prevent single points of failure and ensure continued functionality during emergencies. This includes backup power for pumps, ensuring the system can operate during electrical outages. Secondary control mechanisms for gates ensure manual or mechanical operation is available if automated systems malfunction.

In practice, this redundancy extends to portable, gas-powered hydraulic power units that can be quickly integrated into the system through strategically designed quick-disconnect fittings. Additionally, manual hand pumps and valves provide reliable backup options. These redundant systems give DEP teams confidence that operations can continue under any scenario, while maintaining the highest standard of flood-control reliability.

Contamination Control and Fluid Quality Management: Protecting System Integrity

Hydraulic fluid is the lifeblood of every hydraulic system, and maintaining its purity is essential for long-term reliability. Contamination, from water, air, or particulates, is a leading cause of premature wear, inefficiency, and system failure. We rely on advanced contamination control strategies to prevent issues and safeguard critical components.

High-performance filtration keeps particulates out. Engineered reservoir designs maintain proper fluid flow and reduce the likelihood of contamination entering the system. Routine fluid analysis helps identify early signs of degradation, allowing corrective action before failures can occur. In highly humid or corrosive environments, bladder-style reservoir breathers such as the Parker Kleenvent system create a sealed barrier that isolates the reservoir’s internal air. This prevents moisture intrusion and helps maintain optimal viscosity and lubrication properties.

These contamination control measures significantly extend equipment life and support dependable system performance for DEP operations.

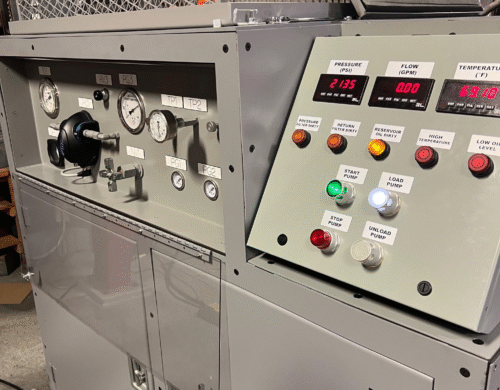

Real-Time Monitoring and Early Warning Systems: Acting Before Problems Escalate

Flood control reliability depends not only on strong design but also on precise, timely information. Real-time monitoring provides DEP operators with visibility into system performance and enables preventive action before issues become critical.

Our hydraulic systems integrate sensors that track oil-water levels, particulate content, accumulator pressure, temperature, flow rates, and other essential parameters. Automated alerts and data-tracking tools help operators detect anomalies early and respond quickly. This early-warning capability dramatically reduces the risk of unexpected downtime, allowing the DEP to operate with confidence and control, even under rapidly changing conditions.

Durable, Corrosion-Resistant Materials: Built to Withstand Harsh Environments

Flood control systems are routinely exposed to corrosive, wet, and high-stress environments. To ensure longevity and performance, it’s important to prioritize durable, corrosion-resistant materials in every project. Components such as gates, pipes, housings, and structural elements are fabricated from marine-grade aluminum, stainless steel, and other proven materials engineered specifically for outdoor and submerged applications.

This material integrity is a must for resisting corrosion, reducing long-term maintenance costs, and preventing structural failures during storm events. When the DEP relies on a system to perform, even in extreme weather, they trust Atlantic’s materials and construction quality to hold up year after year.

A Proactive and Rigorous Maintenance Program: Keeping Systems Ready for Action

Even the most advanced engineering requires ongoing care. Our proactive maintenance approach aligns closely with DEP expectations. This includes scheduled inspections, calibration of sensing devices, performance testing, fluid analysis, and timely replacement of wear-prone components.

A reliable system is one that is maintained long before an emergency arises. Our maintenance procedures ensure each system remains in peak condition, minimizing the risk of unexpected downtime.

Confidence Engineered Into Every System

As storm patterns intensify and infrastructure demands continue to grow, dependable flood control systems are more important than ever.

Atlantic Hydraulic Systems is proud to support the DEP with solutions that emphasize reliability, availability, and long-term performance. If your organization is looking to enhance flood-control reliability or upgrade aging hydraulic infrastructure, Atlantic Hydraulic Systems is ready to help.

Contact us today to discuss your project needs. Your flood control system must be ready when the next storm arrives. Let’s make sure it is.